Contact Infomation

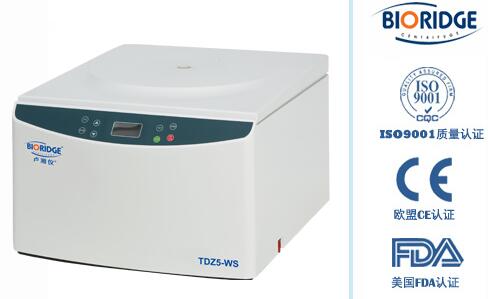

Shanghai Lu Xiangyi centrifuge instrument Co., Ltd.

| Tel: | 86-021-68072892 |

| Fax : | |

| Country/Region : |

|

| Address : | |

| Contact : | sam sam () |

|