Manufacture of hydrogen production equipment by electrolysis of industrial water

Product Description

|

P/N

|

ZXD-5

|

|

Hydrogen Production(m3/h)

|

5

|

|

Oxygen Production(m3/h)

|

2.5

|

|

Hydrogen Purity(V/V)

|

≥99.8%

|

|

Oxygen Purity (V/V)

|

≥92.5%

|

|

Operating load

|

50%~100%

|

|

Working Pressure(MPa)

|

1.5~30

|

|

Hydrogen Moisture Content (g/m3)

|

≤4

|

|

Hydrogen Alkalinity(mg/m3)

|

≤1

|

|

Working Temperature(℃)

|

85±5

|

|

Cooling water flow(m3/h)

|

1.3

|

|

DC power consumption

(kW·h/m3H2)

|

≤4.3

|

|

External dimension of electrolyzer

L×W×H (mm)

|

940×850×780

|

|

Electrolyzer Weight (kg)

|

1350

|

|

Alkali concentration

|

30% KOH

|

|

Circulation quantity of alkali liquor

(m3/h)

|

0.3~0.35

|

|

KOH consumption (normal operation(kg/unit)

|

45

|

Projects show

|

h2 fuel

|

electrolysis for hydrogen production

|

|

alkaline water electrolysis

|

electrolyzer hydrogen

|

|

power storage

|

hydrogen for power generation

|

|

electrolyzer machine

|

water electrolysis plant

|

|

hydrogenics electrolyzer

|

green hydrogen

|

|

electrolyzer companies

|

green hydrogen companies

|

|

electrolysis of alkaline water

|

green hydrogen electrolysis

|

|

electrolyser companies

|

green hydrogen uses

|

|

pem electrolyser cost

|

solar hydrogen production

|

|

hydrogen production system

|

solar electrolysis for hydrogen production

|

More details: **** | sales1@zxdh2.com

Company Information

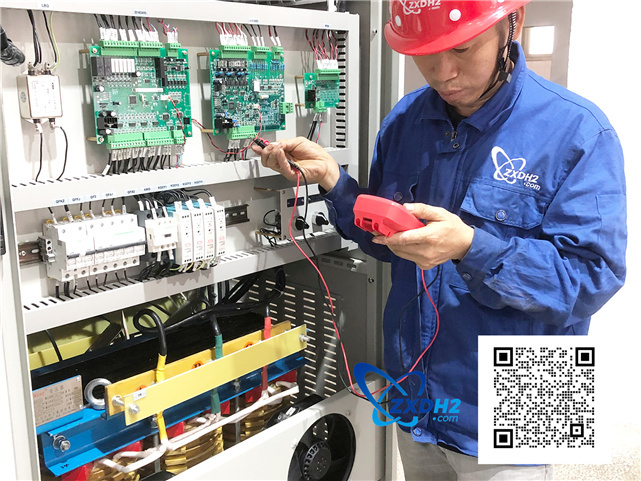

Zhongxinda is committed to the full ecological coverage of hydrogen energy. We can independently complete the design,

on-site installation, commissioning, start-up and operation, maintenance,

overhaul and technical upgrading of the whole hydrogen generation and supply station,

and provide timely and effective after-sales service

The

material of process pipeline is 316L SS stainless steel, which is used

for H2 gas pipeline, O2 gas pipeline and alkali circulation pipeline.

The design of the pipe size is accurate to ensure that the flow rate of

the gas passing through the pipe is within the limits of the

international standard code.

The

pneumatic regulating diaphragm valve imported from the United States is

used to regulate the working pressure, the pressure difference between

the level of H2 alkali and the level of O2 alkali and the working

temperature.

Our service

Pre-Sales Service

* Inquiry and consulting support.

* Technical proposal support.

* View our Factory.

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

sales1@zxdh2.com | +86-18030235311